60 mil HDPE Liner

A 60 mil HDPE liner is a robust and durable material commonly used in various applications, such as waste containment, water storage, and environmental protection. With a thickness of 60 mils, this liner offers excellent puncture resistance and tensile strength, making it suitable for demanding environments. HDPE liners are highly resistant to chemicals, UV radiation, and temperature fluctuations, which contributes to their longevity and effectiveness in preventing leaks and contamination. They are often used in landfill projects, aquaculture, and as liners for ponds and reservoirs. The installation of a 60 mil HDPE liner typically requires careful planning and preparation, including proper site grading and the use of appropriate accessories to ensure seams are secure and watertight. Due to its versatility and reliability, this type of liner is a popular choice among engineers and contractors looking for an effective solution to manage liquids and protect the environment.

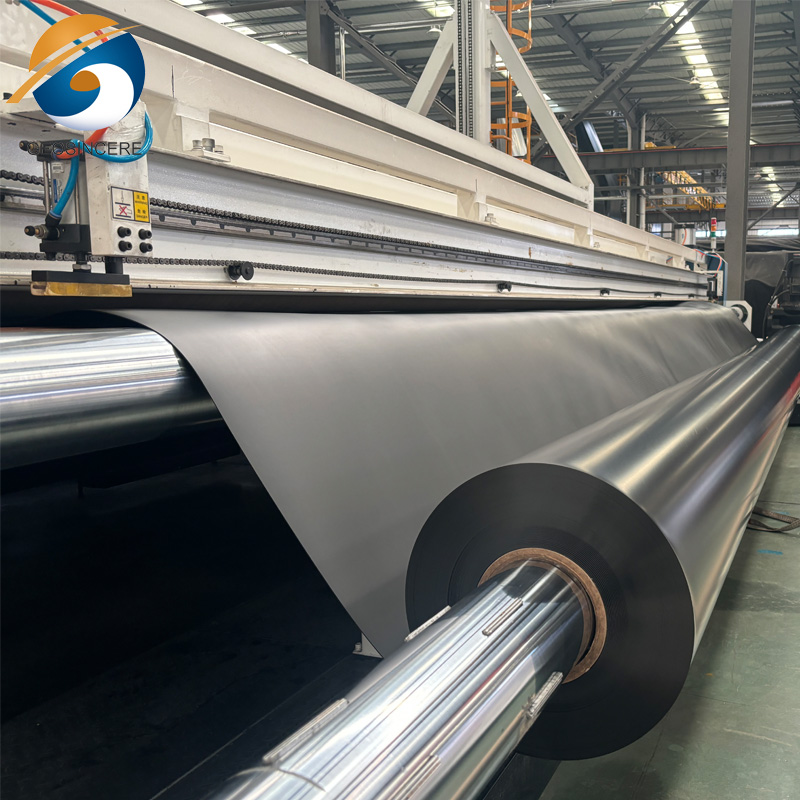

A 60 mil HDPE liner is a robust and durable polyethylene sheet used widely in various applications, including environmental protection, agriculture, and construction. This thickness, measuring 60 mils or approximately 1.5 mm, offers significant resistance to punctures, tears, and UV radiation, making it an ideal choice for lining ponds, landfills, and containment areas. The HDPE material is known for its excellent chemical resistance, enabling it to withstand exposure to a wide range of substances without degrading. Additionally, its flexibility allows for easy installation and adaptation to various shapes and surfaces. The liners are available in large rolls, facilitating coverage of extensive areas, and they can be heat welded or mechanically fastened to create secure seams. The longevity of a 60 mil HDPE liner often exceeds several decades, providing a reliable solution for projects requiring effective barrier systems to prevent leakage and contamination. Overall, this liner is a preferred option for those seeking a combination of strength, durability, and environmental safety in their containment solutions.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | g/cc | D1505/D792 | 90.000kg | 0.94 | |||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

60 mil HDPE Liner Features

- Durability: The 60 mil thickness provides exceptional resistance to punctures and tears, making it suitable for high-stress applications.

- Chemical Resistance: HDPE liners are highly resistant to a wide variety of chemicals, including acids, bases, and solvents, ensuring long-term performance in demanding environments.

- UV Stability: These liners are designed to withstand prolonged exposure to ultraviolet (UV) rays, preventing degradation and maintaining their integrity over time.

- Flexibility: The material's flexibility allows for easy installation and adaptation to various shapes and surfaces, making it ideal for uneven terrains.

- Seam Strength: 60 mil HDPE liners can be heat welded or mechanically joined, providing strong seams that enhance the overall strength and leak prevention of the liner.

- Environmental Protection: Used in applications such as landfills and ponds, these liners help prevent soil and water contamination, ensuring compliance with environmental regulations.

- Longevity: With a lifespan of several decades, 60 mil HDPE liners offer a cost-effective solution due to their reduced need for replacement.

- Easy Maintenance: The smooth surface of HDPE liners makes them easy to clean and maintain, ensuring optimal performance throughout their lifespan.

- Versatility: Suitable for various applications, including agricultural, industrial, and municipal uses, providing effective containment solutions across different sectors.

Applications of 60 mil HDPE Liner

- Landfills: Used as a protective barrier to prevent leachate from contaminating groundwater, ensuring environmental safety and compliance with regulations.

- Ponds and Reservoirs: Ideal for lining ponds, reservoirs, and water features, preventing water loss due to seepage and maintaining water quality.

- Agricultural Uses: Employed in agricultural applications such as irrigation ponds, aquaculture, and agricultural runoff management to protect water sources and enhance crop productivity.

- Mining Operations: Utilized in mining sites for waste containment and tailings management, effectively preventing environmental contamination from hazardous materials.

- Wastewater Treatment: Applied in lagoons and treatment facilities, helping to contain wastewater and prevent leaks into surrounding soil and water bodies.

- Environmental Remediation: Used in remediation projects to contain contaminated soil or hazardous waste, ensuring safe disposal and preventing further environmental impact.

- Construction Projects: Implemented in various construction applications, including temporary site containment for dewatering or sediment control during excavation.

- Stormwater Management: Effective in stormwater retention ponds and bio-swales, helping to manage runoff and protect local waterways from pollutants.

- Geothermal Applications: Used in geothermal installations to create barriers that prevent heat loss and protect surrounding areas from potential contamination.

- Recreational Uses: Lined artificial lakes, golf course ponds, and other recreational water features to enhance aesthetics and functionality while preventing seepage.

Product Packing

Selling Packing:Customer's company Logo mark can be designed and added.

Outer Packing:Packed in Double-layer woven bags to ensure smooth arrival and avoid rough handling.

Transport Packing: Put in the container.

Company Profile

Shandong GEOSINO New Material Co.,Ltd (Brand:Geosincere) is the professional geomembrana and geosynthetics manufacturer and wholesaler located in Taian City, Shandong Province, PRChina. We are not a local overseas distributer, we are an professional manufacturer, exporter and wholesaler for such geosynthetic products as geomembana, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc. GEOSINCERE is always committed to geomembrana research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembrana and geotextiles for civil, mining, environmental and aquaculture engineering applications.

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality geomembrana and other geosynthetics with optimized processes. GEOSINCERE has over 160 employees and its own 24,000 square meters state-of-art manufacturing factory with many automatic geosynthetic production lines, professional machines and testing equipment.Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geomembrana and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

Hope to be your partner!